OFF ROAD OIL REPORTS BEFORE AND AFTER INSTALL

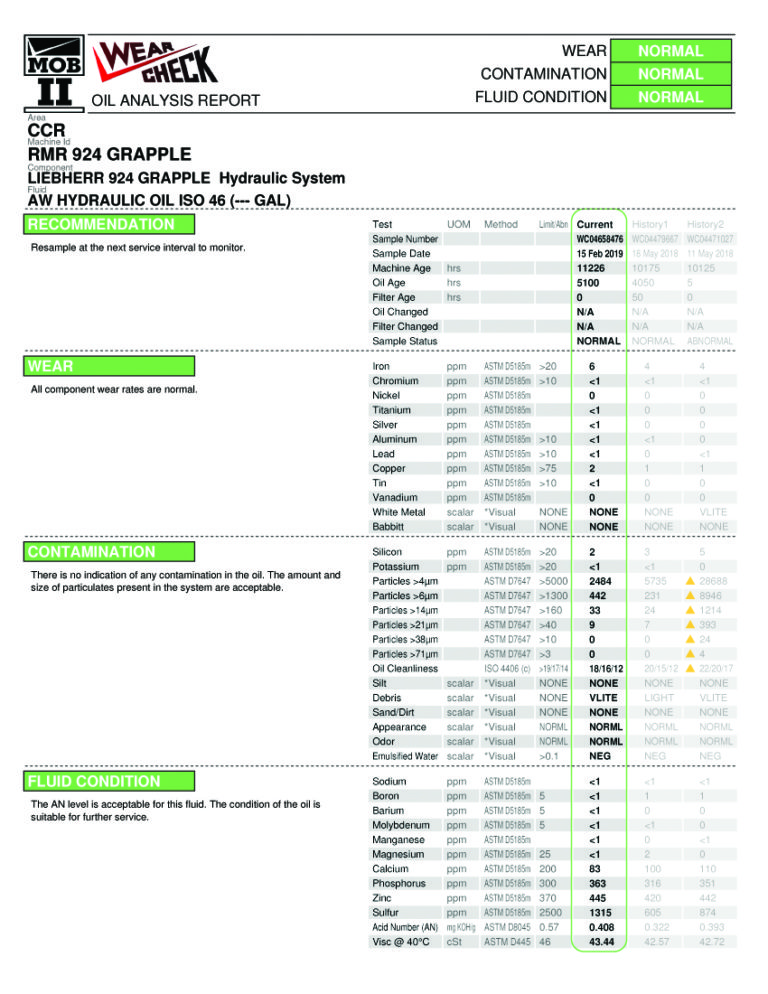

LIEBHERR MAGNET

This Liebherr magnet machine had contaminated hydraulic fluid and since new pumps cost over $30k, they went with hydraulic purifiers to protect them. The baseline particle counts were flagged caution and over time were cleaned up by over 91%.

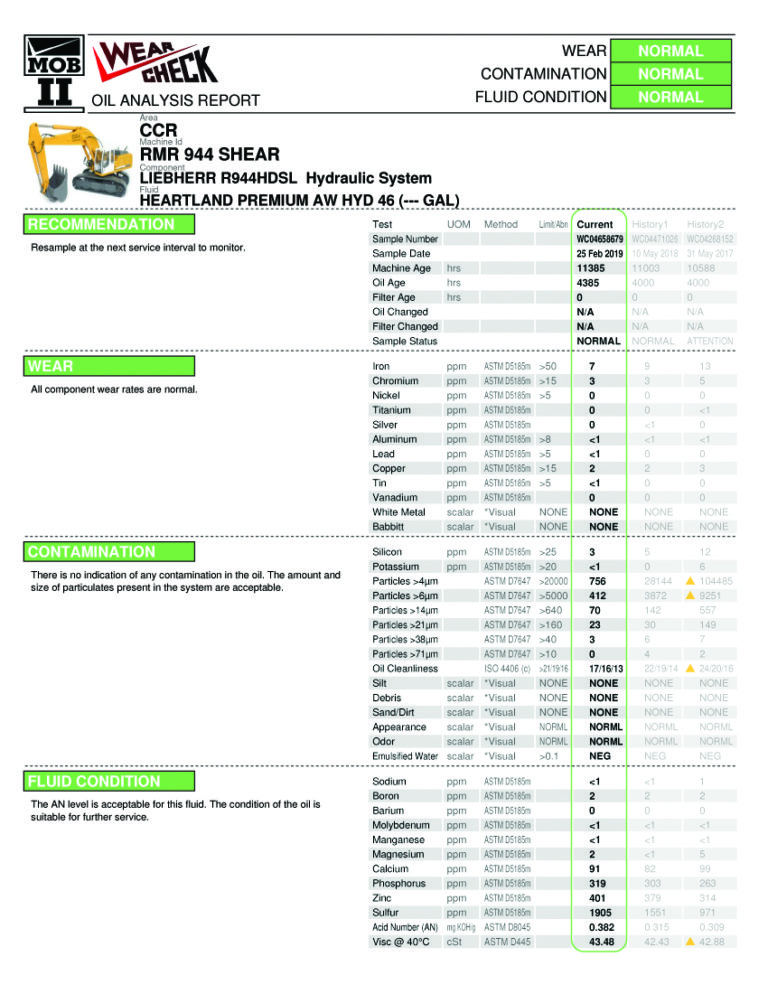

RECYCLING SHEAR

This recycling shear machine had extremely contaminated oil from operating in very harsh conditions. The particle counts were flagged as caution and were cleaned up by over 99% with the purifier and the oil hasn't been changed since.

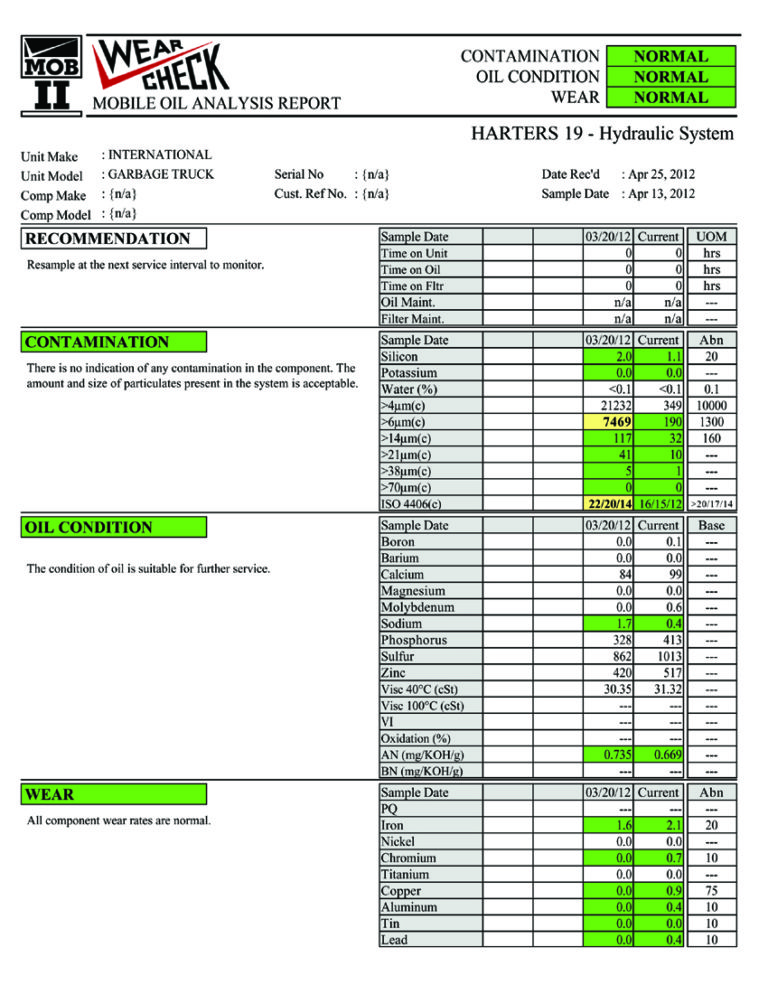

GARBAGE TRUCK

This garbage truck hydraulics had a significant drop of 98% less particle for both 4 and 6 micron sizes. The before oil sample was flagged as caution for high particles and was cleaner than new oil afterwards.

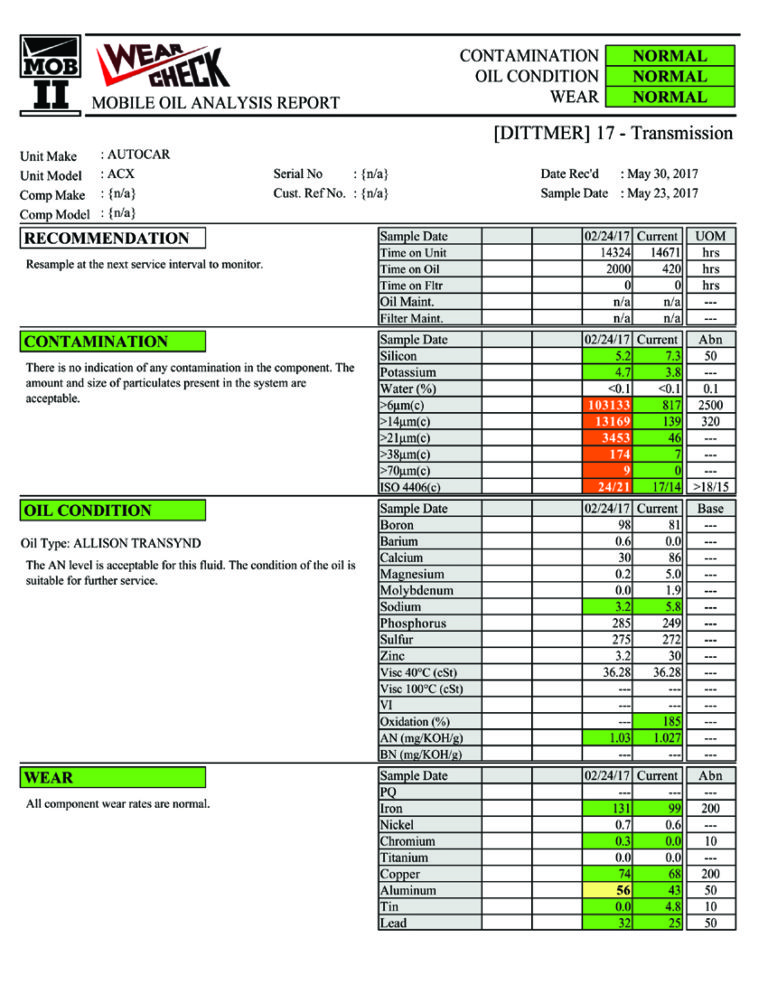

ALLISON TRANSMISSION

This garbage truck with a Allison transmission had severe contamination and high wear metals as a result. After installation the particle count was over 99% cleaner than before with less wear metals.

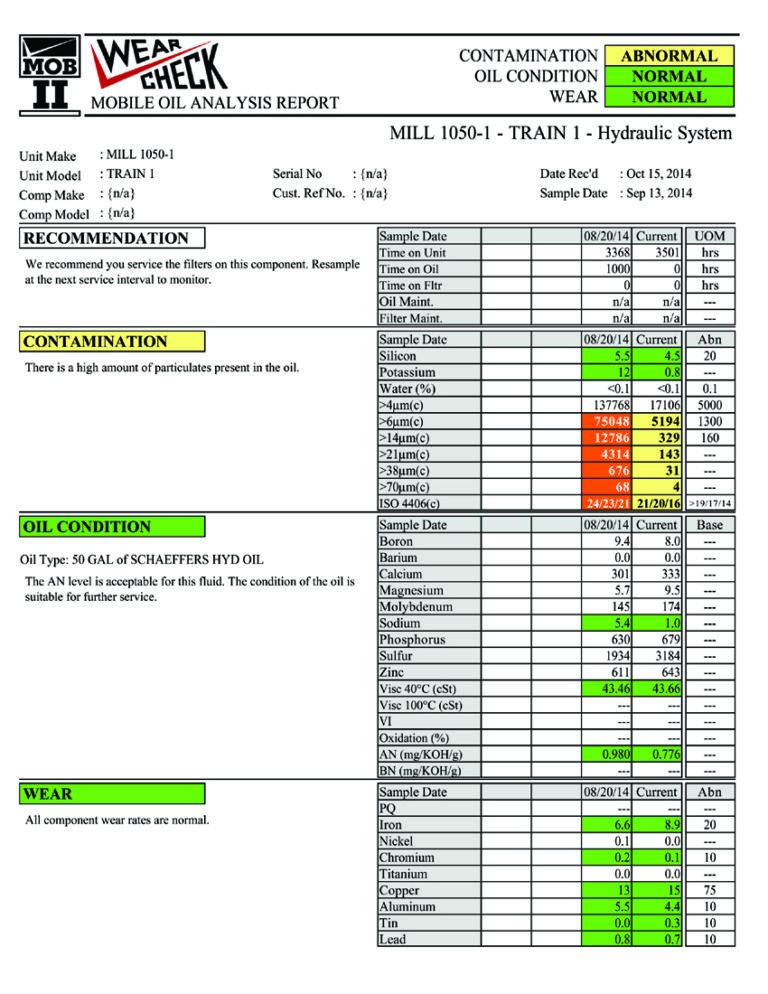

ASPHALT MILLING

This asphalt milling machine had severely contaminated hydraulic fluid, and pumps would fail once every couple months causing costly downtime. After only 133 hours of the installation the particle count was lowered by 87% overall. They never lost another pump since they chose to go with the purifiers.

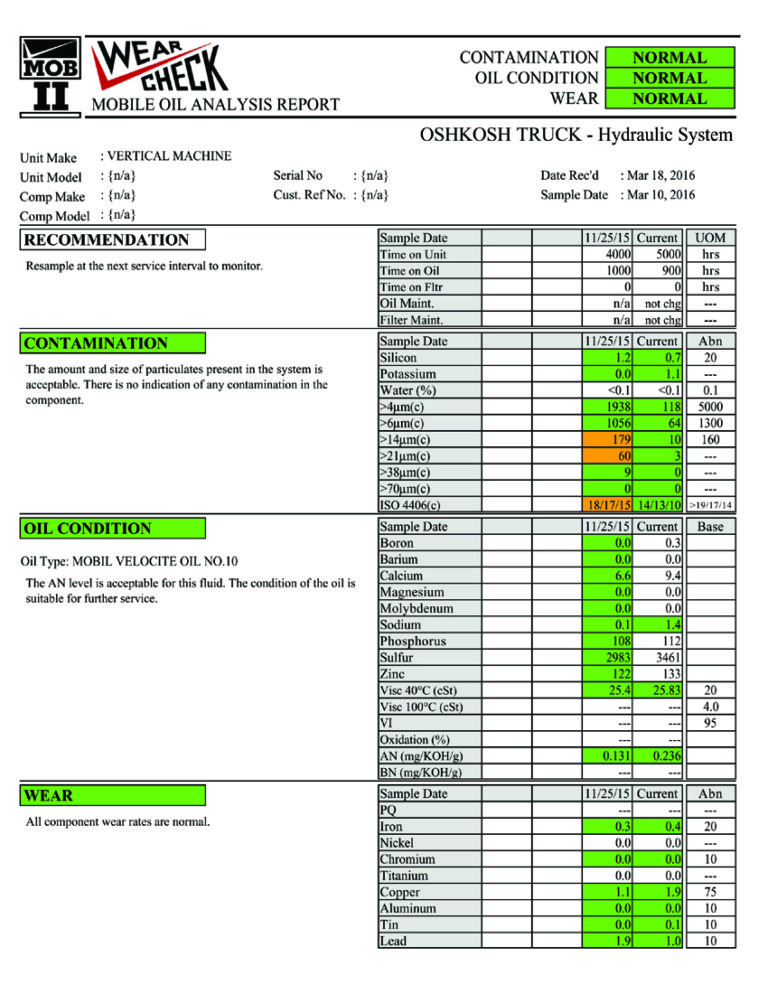

OSHKOSH MANUFACTURING

This coil processing machine has a complex hydraulic system that requires pristine oil in order to maximize up time in their facility. The baseline sample was flagged as caution and was cleaned up by 94% after installation, they will not have to change the oil again.

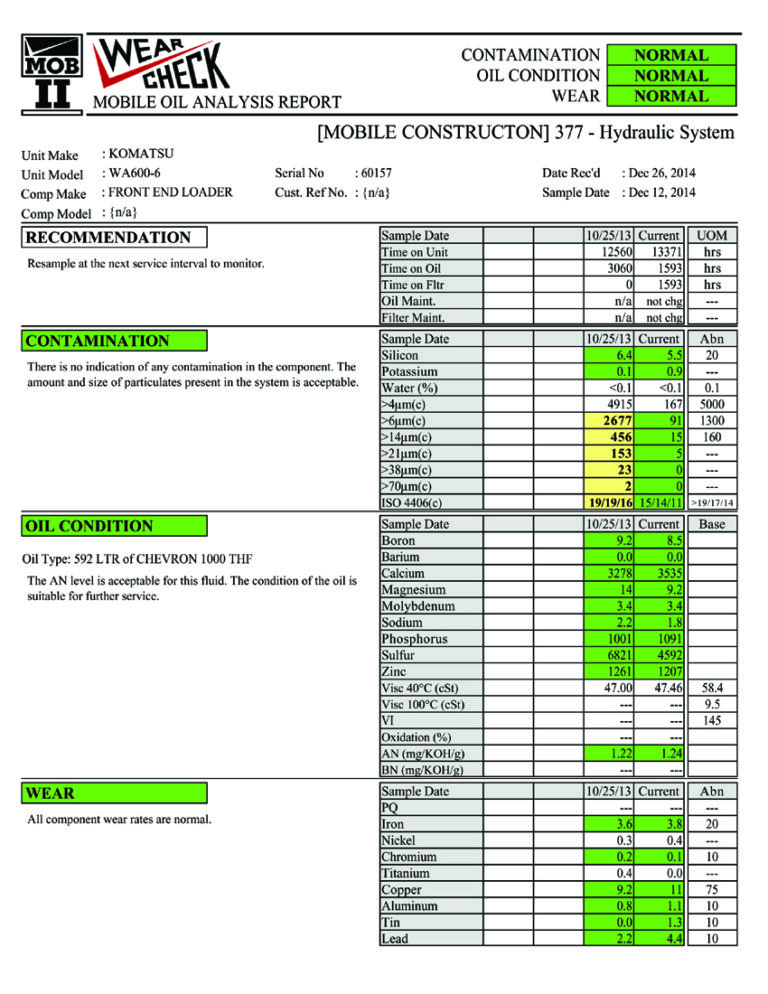

KOMATSU HYDRAULICS

This Komatsu wheel loader had a high amount of contamination in the hydraulic system from working in the quarry. The baseline particle count was flagged as caution and after 2 months and 811 hours with the purifier the particle count was 96% lower than before.

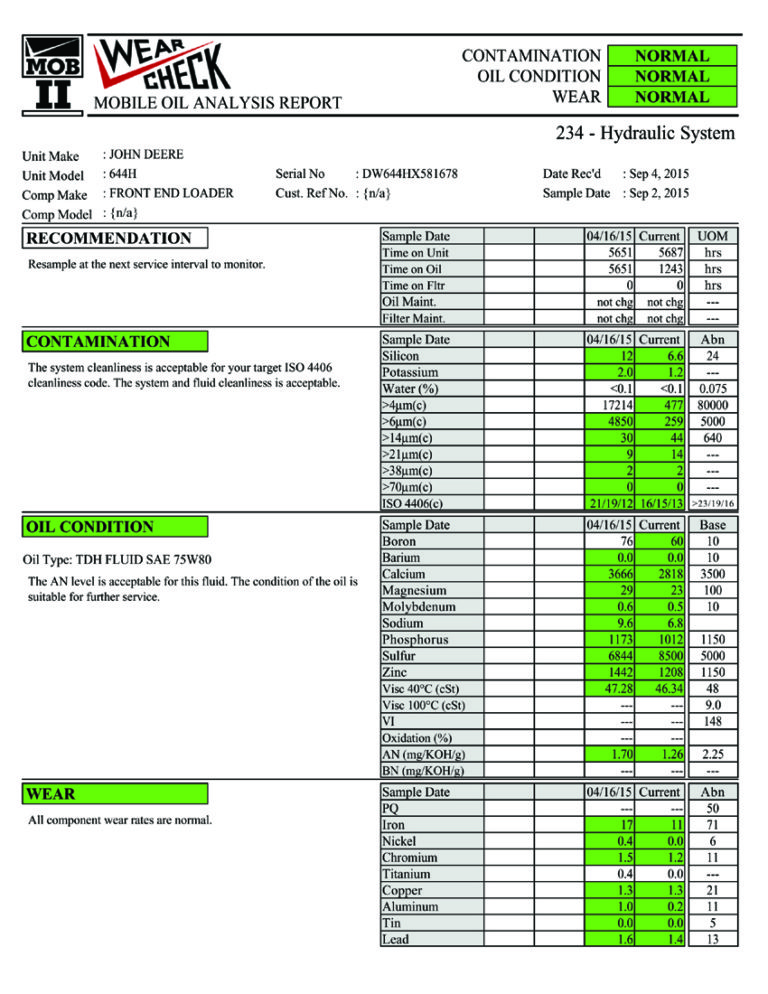

DEERE HYDRAULICS

This John Deere loader had a high baseline particle count and after only 36 hours on the purifier it was able to remove over 97% of the dirt from the hydraulic system without having to change the oil. The wear metals were also reduced as a result of the purifier.

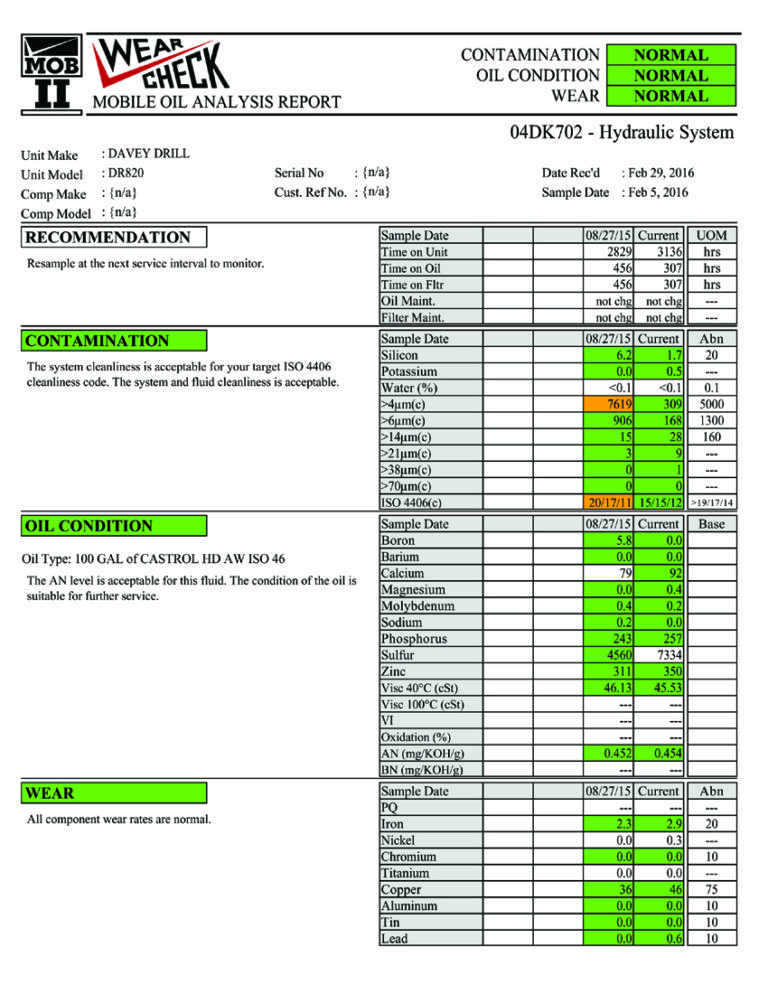

DAVEY HYDRAULICS

This Davey drill had a high amount of contamination in the hydraulic system from drilling in the quarry. The baseline particle count was flagged as caution and after 307 hours operating with the purifier the particle count was 96% lower than before.

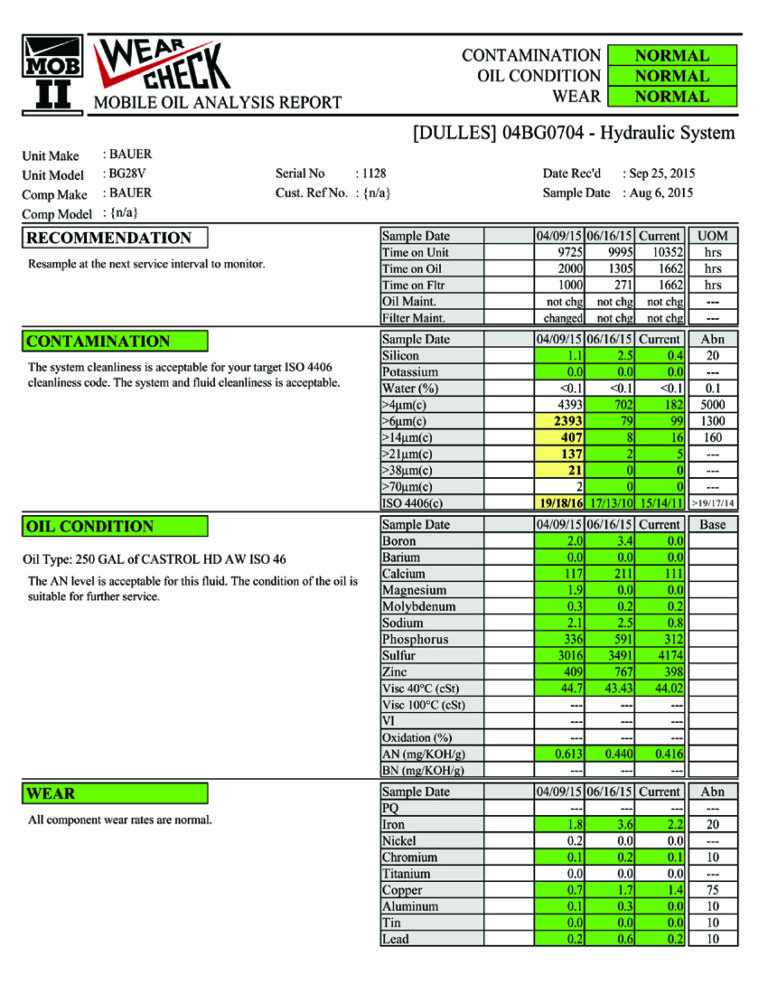

BAUER HYDRAULICS

This Bauer BG28 drill had a high baseline particle count and after 627 hours on the purifier it was able to remove over 96% of the dirt from the hydraulic system. Restoring the hydraulic fluid back to the acceptable ISO 4406 cleanliness levels for this machine.