WHAT WE DO

MAXIMIZE UP TIME

Our program is designed to minimize fuel, oil and maintenance costs by keeping the engine, fuel system and emission components clean and soot free for optimal performance and up time

ONSITE INSTALLATION

On site Installation and Training separates us from the others, we offer a hands on approach for our clients giving them the peace of mind knowing that the job is done right the first time

OIL SAMPLE REVIEW

Our team of oil and fuel analysis experts provide real time feedback on critical reports with instant alerts to critical issues and potential downtime

On site Installation and Training separates us from the others, we offer a hands on approach for our clients giving them the peace of mind knowing that the job is done right the first time

Our On Road and Off Road trained staff will visit the Organization to make a proactive plan with the Equipment Manger and Fleet Owner. Together we will determine an installation schedule for the fleet, as the Equipment comes through the shop for other maintenance, this is the most efficient time to install the Clean Air Fleet Oil By-Pass Filtration.

Clean Air Fleet will perform the installation, or we can assist in the installation of the Clean Air Fleet Oil Cleaning Systems initially to get the project started.

Oil Changes are not recommended due to the fact that oil gets old, rather, it gets contaminated. According to traditional maintenance practices, it is better to change oil at recommended intervals. Clean Air Fleet Oil Purification will provide much Cleaner Oil when compared to using a standard full flow by itself.

CLEAN AIR FLEET PROGRAM

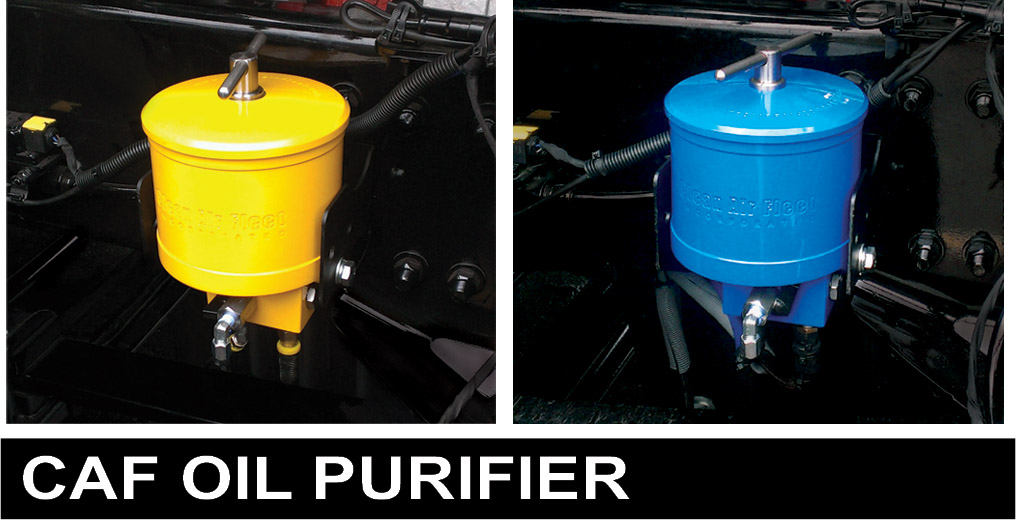

Removes 99.98% of ALL contaminants from the oil allowing to safely double engine oil and engine life

Eliminates water, acids, metals, soot, dirt and dust down to 1 micron protects the engine and turbo

Controls the excess soot, carbon and acid in the oil from the EGR reburning exhaust gases

Reduced carbon packing and blow-by burns less oil with less smoke and ash through the DPF

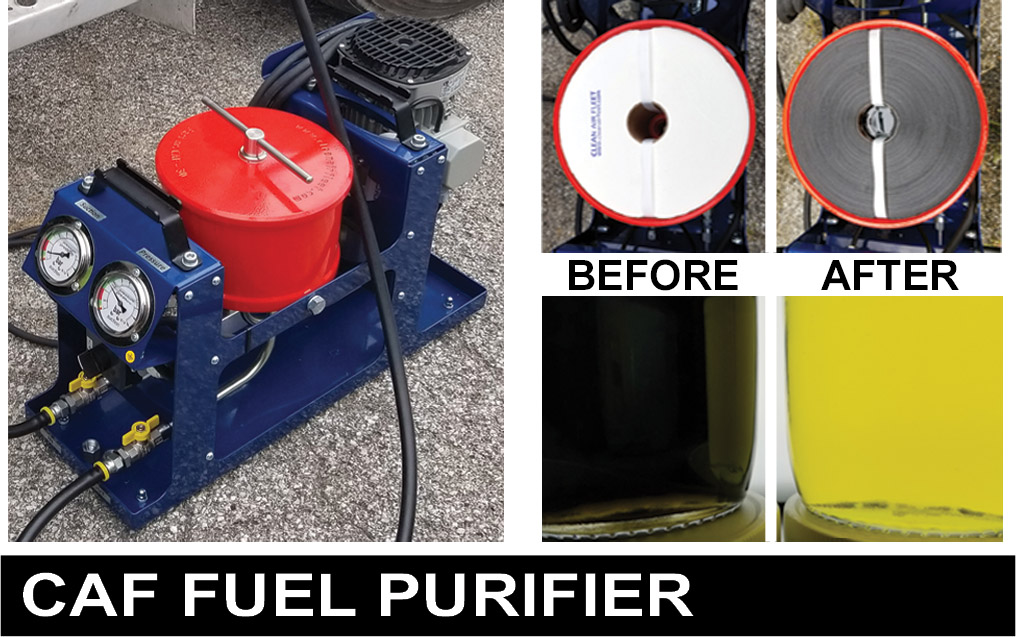

Cleans 99.98% of ALL contaminants from the fuel tanks protecting the entire fuel system from damage

High pressure common rail engines with very tight tolerances require greater fuel cleanliness

Meets injector manufacturer mandates for increased fuel cleanliness and water levels lower than 200 ppm

Removes water, asphaltene, algae, dirt and dust down to 1 micron protects injectors and fuel pumps

The Clean Air Fleet Oil, Fuel and Emission Maintenance Program is designed specifically to address major issues with today’s engines by exceeding the minimum specifications for fuel and oil quality and cleanliness.

An engine that runs on purified oil, polished fuel and premium grade diesel fuel is operating under ideal conditions the way it was designed to function. Less wear and drag with increased lubrication throughout creates a smoother, efficient running motor. Less soot and carbon buildup results in less downtime and maintenance on pumps, injectors, turbos and emission control components.

Creates easier and more accurate dosing of fuel instead of guessing or not treating the fuel at all

Provides safer storage of fuel additive outside of the cab instead of bottles leaking inside the cab

Limits exposure to fumes from chemicals getting stored inside the driver’s sleeping area

Available with either manual operation by the driver or fully automatic additive dosing to the fuel tanks

Restores lost lubricity back to 3000 ppm sulfur fuel equivalent to properly protect pumps and injectors

Improves the air/fuel ratio with more complete burn of the fuel producing less emissions

Lowers smoke and soot throughout the emission system sensors, EGR, 7th Injector and DPF

Better cetane and ignition lowers cylinder temps and NOx resulting in noticeably less DEF use