According to a study done at MIT, approximately 70% of all equipment’s usefulness loss is due to surface degradation. In a case study performed by General Motors and published by the Society of Automotive Engineers (SAE), it was determined that engine service life could be extended EIGHT TIMES when 5-micron filtration is implemented vs. the standard 40-micron filtration.

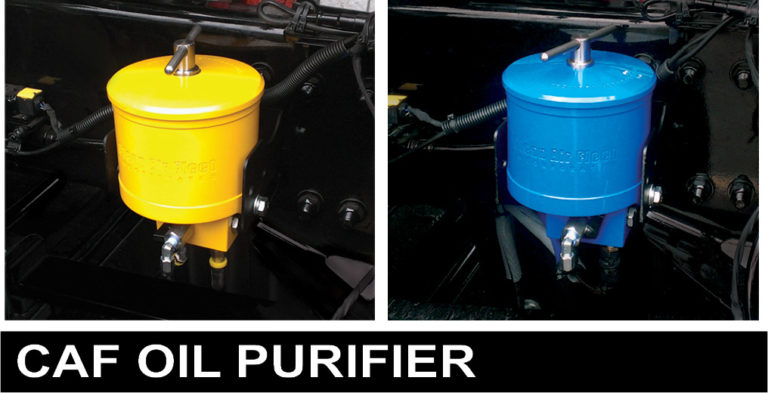

The CAF Bypass Oil Purifier system is plumbed into your oil system and will clean your oil and its reservoir by separating and removing contaminants, water, metal and acid. With the CAF Oil Purifier the flow rate is greatly reduced, allowing for a much smaller pore size while retaining a normal pressure differential. The result is much cleaner oil being returned to the sump.

With a standard spin-on filter, the damaging small micron particles that are not controlled by the 30µ full-flow filter will now be removed from the system. The oil cleaner will safely extend the serviceable life span of your Engine oil by 2 or more times the regular interval. Hydraulic and Gear oil is purified to cleaner than new oil from the barrel with the lifespan extended up to 10 times than normal.

These fluid savings along with the benefits from better performing engines, reduced wear and tear on components and prevention of premature failures will have an enormous impact on the profitability and sustainability of your operation for years to come.

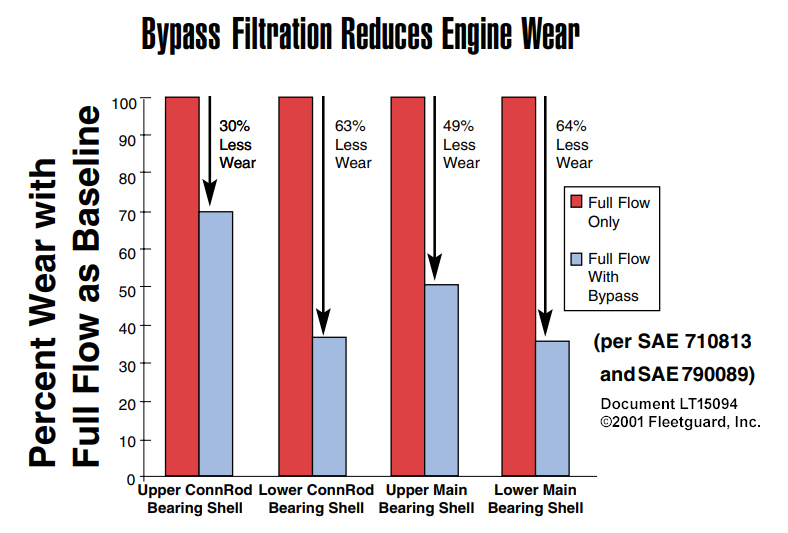

According to a study performed by Cummins Engine Manufacturer, By Pass Oil Filtration Reduces Engine Wear significantly over the spin on filter.

They performed this test using SAE tests 710813 and 790089 to measure the actual difference between the standard full flow filter rated at 30 micron vs ultra fine depth media filtration rated at 5 micron or lower.

• The Upper Connecting Rod Bearing wear was reduced by 30%

• The Lower Connecting Rod Bearing wear was reduced by 63%

• The Upper Main Bearing wear was reduced by 49%

• The Lower Main Bearing wear was reduced by 64%

The Oil Cleaner system consists of a metal housing which holds 100 yards of ultra fine four stage filtration media. Maintenance and upkeep after installation is changing the filter element at the standard interval, taking a sample for analysis, and topping off with oil. Instant savings can be calculated immediately on reduced oil and filter use, waste oil disposal, labor and downtime for services. The real long term savings comes from lower maintenance, related downtime and overall extended rebuilds on equipment.

A standard full flow filter has up to ⅛ inch thickness of filter media, compared to our element which is over 4 inches of filter medium. Our elements are constructed from a specifically designed cellulose fiber material that absorbs water and oxidation residue as well contaminants down to 1 micron in size. Manufactured with a patented CNC winding and cutting machine for maximum accuracy and quality control. All filter elements are tested according to the Multipass Test ISO 4572 which ensures that every micron rating we state results from extensive testing performed by a certified Multipass Test Laboratory.